Duraklean? SL filters have been developed for the classification of a variety of formulated slurry products. Duraklean? SL filter relies on either a graded-density or porosity depth filter design that enables it to remove defect-causing particles in each of its graded depth filter matrix. The particle size distribution of the desired slurry particles and solid content do not change after filtration. As a result, slurry quality is consistently delivered to manufacturing processes. Duraklean? SL filters can be expected to provide excellent particle retention and yield long service life resulting in low total filtration costs.

DuraKlean? SL filter is a line of all polyolefin depth filters, and is rigid-structured filters designed to overcome many of the deficiencies a typical melt-blown filter may encounter. The filter matrix is constructed using non-surfactant treated long bi-component fibers, each fiber has an inner polypropylene core and an outer polyethylene sheath. The filter matrix’s bi-component PE/PP fibers are thermally bonded at fiber-to-fiber contact points. The high degree of fiber-to-fiber bonding results in a clean and rigid filter structure.

This rigid structure eliminates both the need for a core and the possibility of unloading trapped contaminants due to media migration. Furthermore, the rigid structure retains its porosity structure while the graded depth structure removes a variety of particulates including deformable agglomerates that are disruptive to the CMP process. Because particles are retained throughout the filter matrix rather than on a single surface, the potential for premature filter“plugging”is greatly reduced. The resulting DuraKlean? SL filters offer consistent and reproducible filtration performance throughout the filter service life.

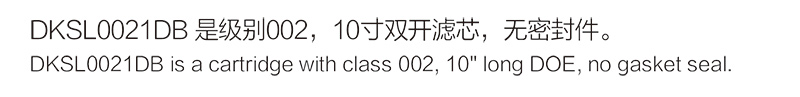

Utilizing state-of-the-art manufacturing technology, DuraKlean? SL filter grade 002, 003, 005, and 010 are engineered to combine an inner section formed by thermally bonded PE/PP fiber matrix and outer section formed by graded porosity PP non-woven filtration media(as shown in the lower-right image). Inner section is rigid structure having uniform pore providing reliable filtration. Outer section combines graded porosity and depth structure with a built-in pre-filtration layer positioned at the upstream side providing extended filter service life.